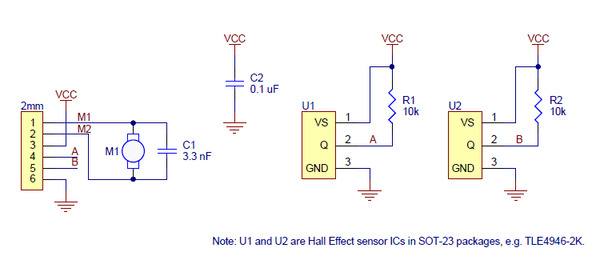

| Electrical Specifications | |

| Minimum Operating Voltage | 2.7 V |

| Maximum Operating Voltage | 18 V |

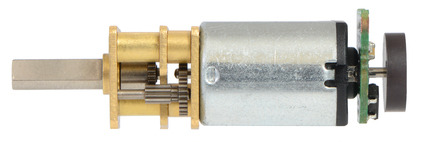

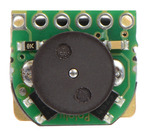

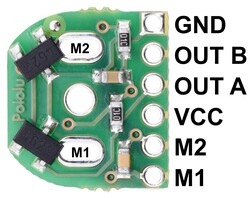

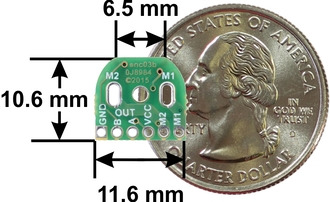

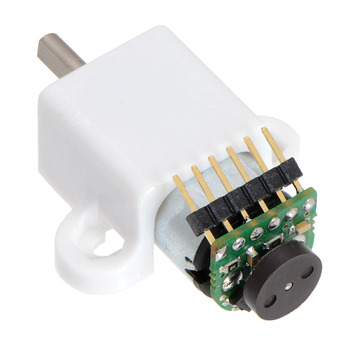

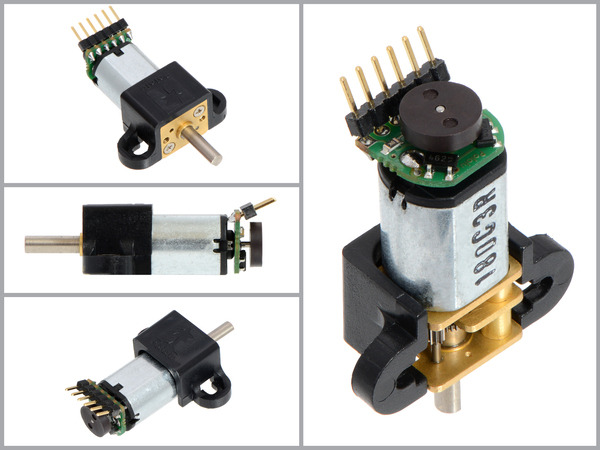

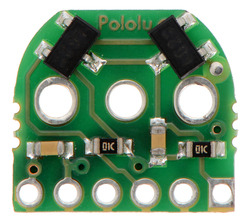

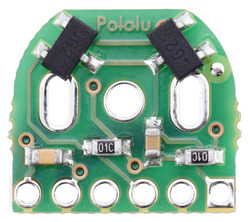

Pololu 3081 Magnetic Encoder Pair Kit for Micro Metal Gearmotors

- Brand: Pololu

- Product Code: Pololu-Magnetic-Encoder-Micro-Metal-Gearmotors

- Reward Points: 7

- Availability: In Stock

- रo 786.00

-

रo 754.00

- Price in reward points: 786

-

- 25 or more रo 751.00

- 50 or more रo 745.00

- 100 or more रo 718.00

Related Products

Pololu 4760/4761 Magnetic Encoder Pair Kit - 12 CPR, 2.7-18V

Add quadrature encoders to your micro metal gearmotors (extended back shaft version required) with t..

रo 679.00 रo 707.00

Pololu 2826 Metal Gearmotor 37Dx73L mm with 64 CPR Encoder

This gearmotor is a powerful 12V brushed DC motor with a metal gearbox and an integrated quadrature ..

रo 2,866.00 रo 2,986.00

Pololu 4754 Metal Gearmotor 37Dx70L mm 12V with 64 CPR Encoder - 70:1

This gearmotor is a powerful 12V brushed DC motor with a 70:1 metal gearbox and an integrated quadra..

रo 5,647.00 रo 5,882.00

Pololu 4750 / 4751 / 4752 / 4753 / 4755 / 4756 / 2828 Metal Gearmotors with 64 CPR Encoder (Helical Pinion)

This is the motor and encoder portion of our 37D x L mm metal gearmotors with 64 CPR encoders. It do..

रo 3,497.00 रo 3,643.00

Pololu 2823 Metal Gearmotor 37Dx68L mm with 64 CPR Encoder

This gearmotor is a powerful 12V brushed DC motor with a 30:1 metal gearbox and an integrated quadra..

रo 2,866.00

Pololu 3700/3701/3702/3703/3704/3705/3706/3707/3708/3709/3710/3711 Metal Gearmotor 6V CB

These cylindrical brushed DC gearmotors are available in a wide range of gear ratios, from 25:1 up t..

रo 2,802.00 रo 2,919.00

Pololu 3036/3037/3038/3039/3040/3041/3042/3043/3044/3045/3046 Micro Metal Gearmotor HPCB 12V

These tiny brushed DC gearmotors are available in a wide range of gear ratios—from 5:1 up to 1000:1—..

रo 2,105.00 रo 2,193.00

Pololu 4741 / 4742 / 4743 / 4744 / 4745 / 4746 / 2829 Metal Gearmotors without Encoder (Helical Pinion)

These powerful brushed DC gearmotors are available in a variety of different gear ratios. Versions w..

रo 3,577.00 रo 3,726.00

Pololu 3449 / 3498 Magnetic Encoder Disc for 20D mm Metal Gearmotors

These magnetic discs can be used with our 20D mm metal gearmotors (extended motor shaft versions onl..

रo 67.00 रo 70.00

Tags: Pololu, Micro Metal Gearmotors